There are two transportation equipment that play a key role in standardization of international logistics: Containers and Pallets.

Containers are the main Cargo Transport Units (CTU) in international transportation. They are used to carry Unit Loads (ULD) safely and securely.

The most widely used Unit Loads in international transportation are pallets.

Pallets are designed for easy handling of all types of stackable items such as small cases, cartons or bags.

Pallets standardize cargo transportation and warehousing operations from an exporter’s factory to an importer’s warehouse.

Euro pallets (1200 mm x 800 mm) and Industrial Pallets (1200 mm x 1000 mm) are two most frequently used pallets in international transportation.

On this post you can find standard dry, reefer and pallet-wide container loading plans for palletized goods.

PALLET LOADING PLANS

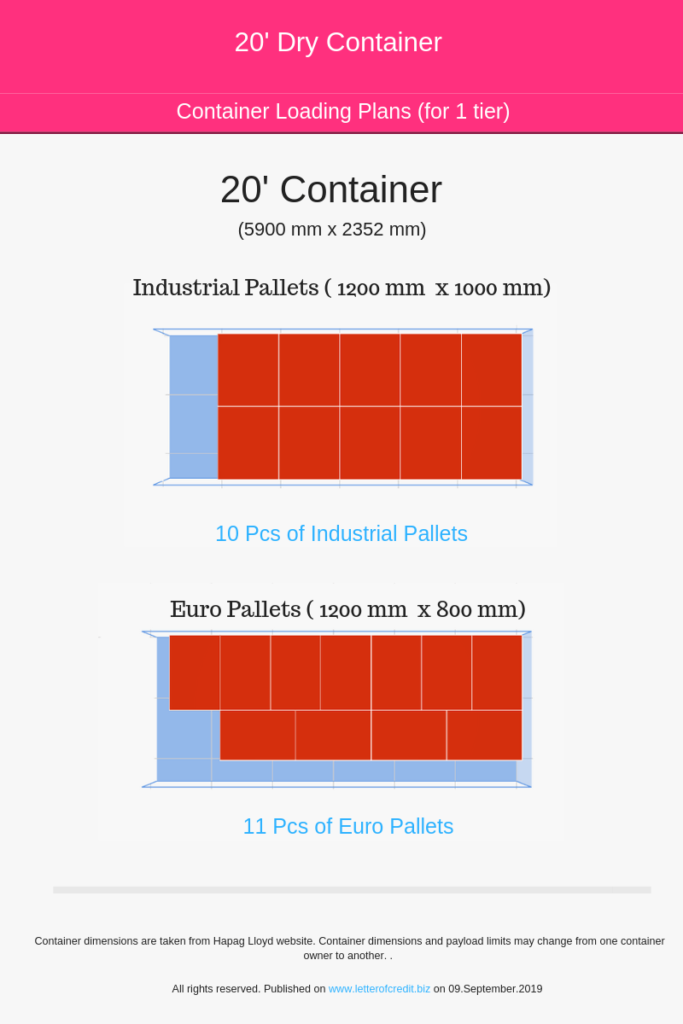

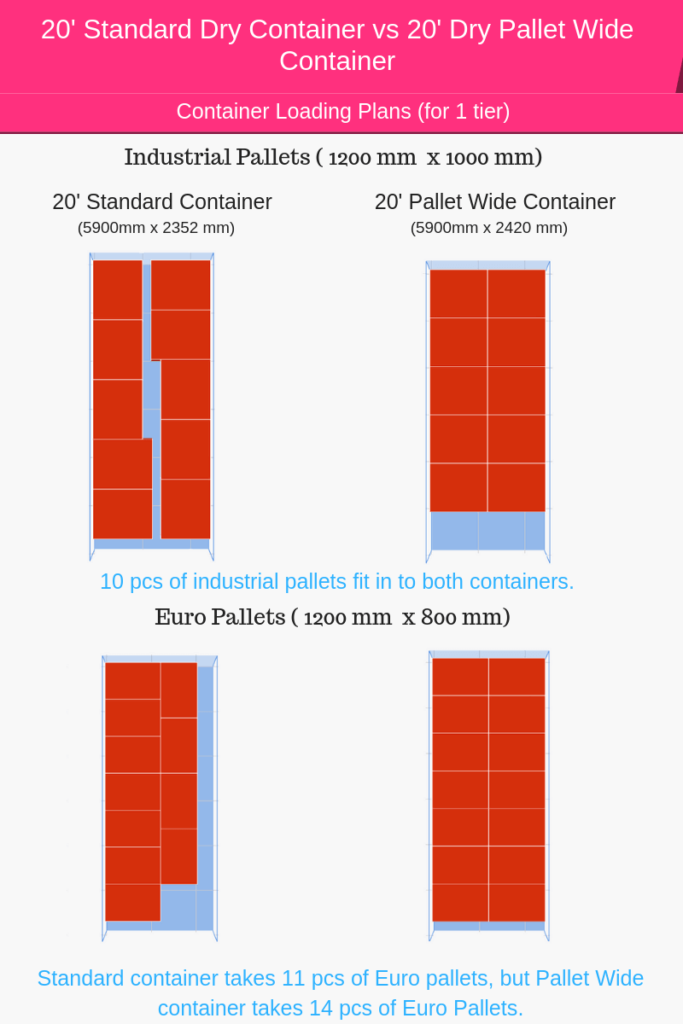

20′ Dry Container Pallet Loading Plans

How Many Pallets Fit in a 20′ Container?

A 20′ container is one of the most frequently used container type in international logistics with the following interior dimensions:

- Length: 5900 mm

- Width: 2352 mm

- Height: 2395 mm

It is possible to fit 10 pcs of industrial pallets and 11 pcs of euro pallets in to a 20′ standard dry container.

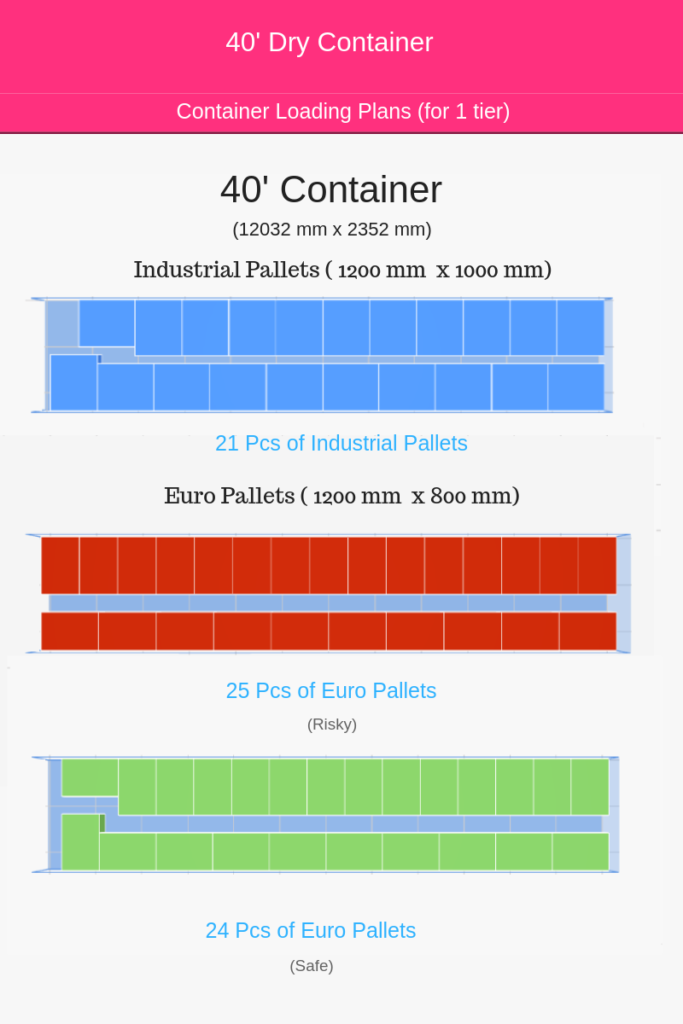

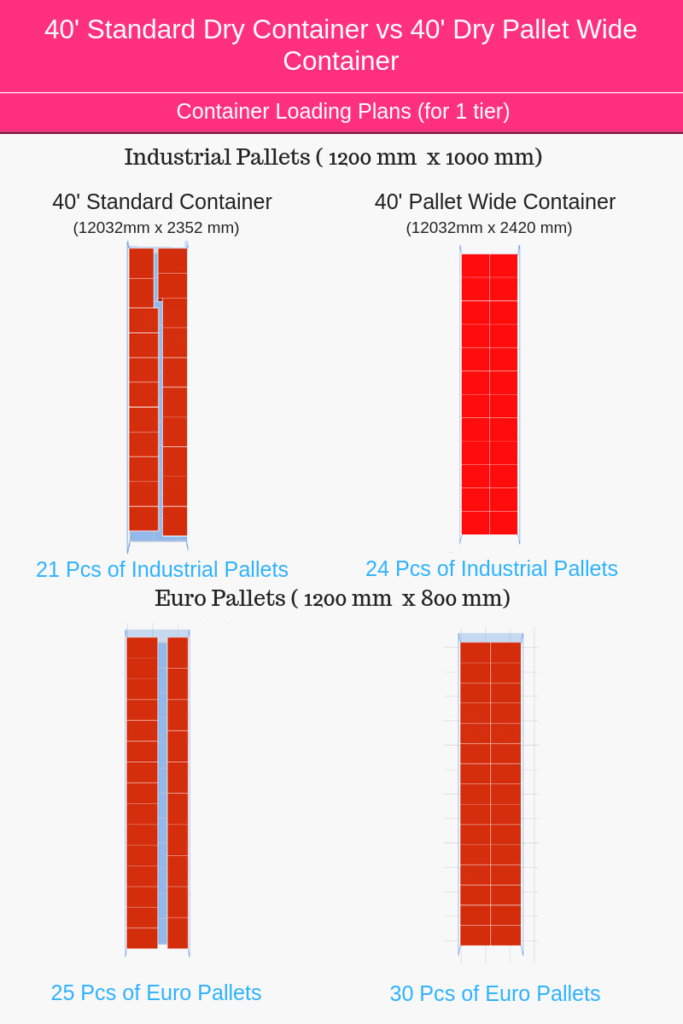

40′ Dry Container Pallet Loading Plans

How Many Pallets Fit in a 40′ Container?

How Many Pallets Fit in a 40′ Container?

A 40′ container is one of the most frequently used container type in international logistics with the following interior dimensions:

- Length: 12032 mm

- Width: 2352 mm

- Height: 2395 mm

It is possible to fit 21 pcs of industrial pallets and 24/25 pcs of euro pallets in to a 40′ standard dry container. (24 is safer)

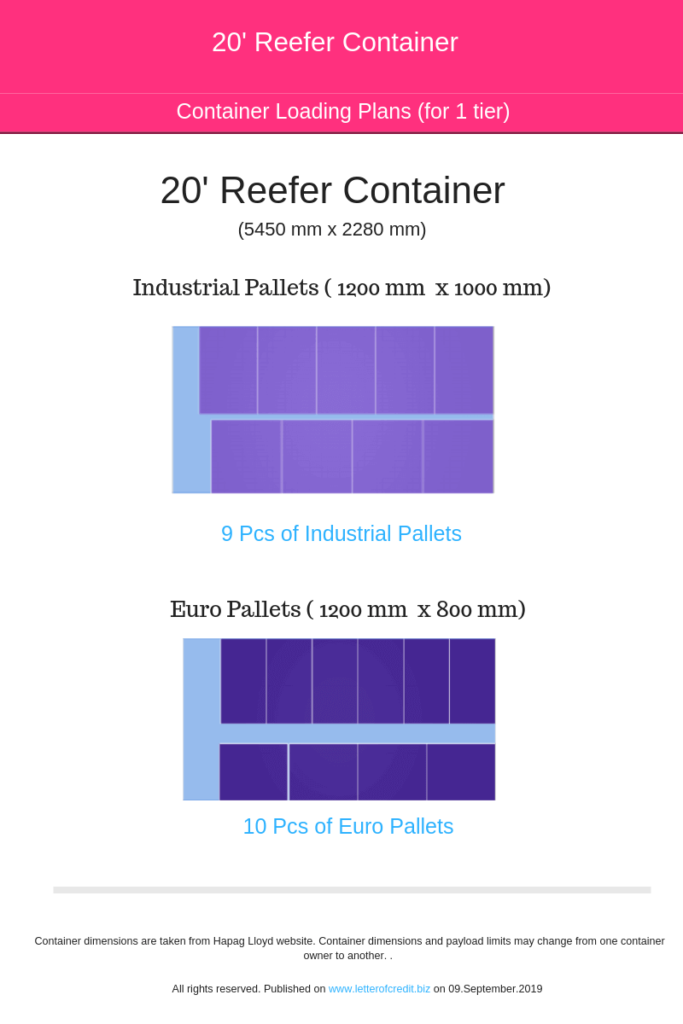

20′ Reefer Container Pallet Loading Plans

How Many Pallets Fit in a 20′ Reefer Container?

Refrigerated containers are designed for the transport of perishable goods in a temperature-controlled environment (from -35°C to +35°C).

20′ reefer container has the following internal dimensions:

- Length: 5450 mm

- Width: 2280 mm

- Height: 2159 mm

It is possible to fit 9 pcs of industrial pallets and 10 pcs of euro pallets in to a 20′ reefer container.

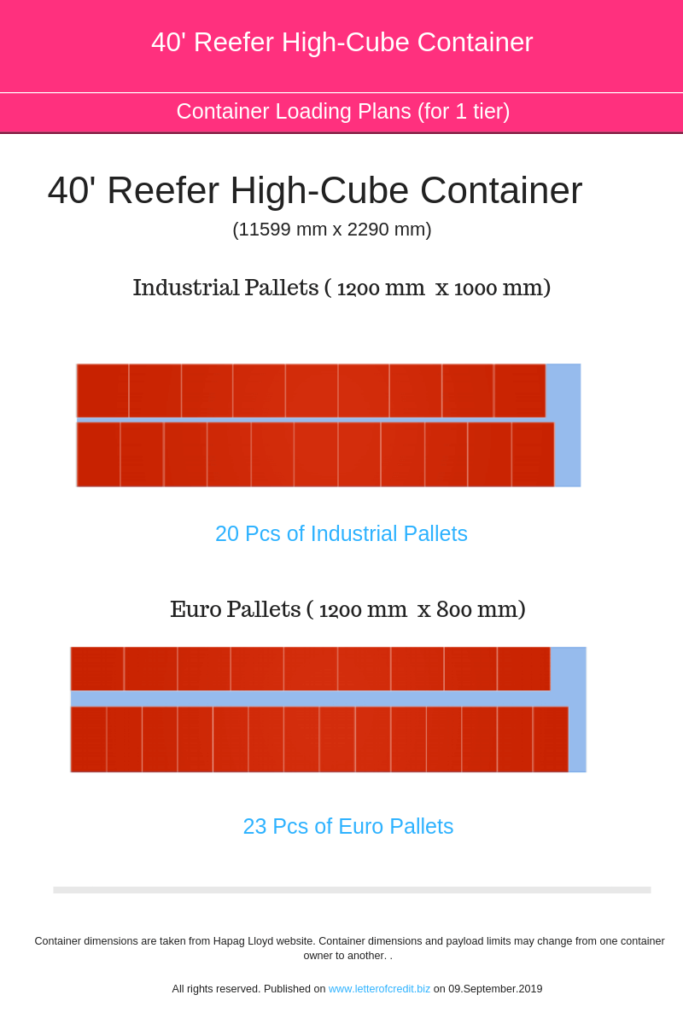

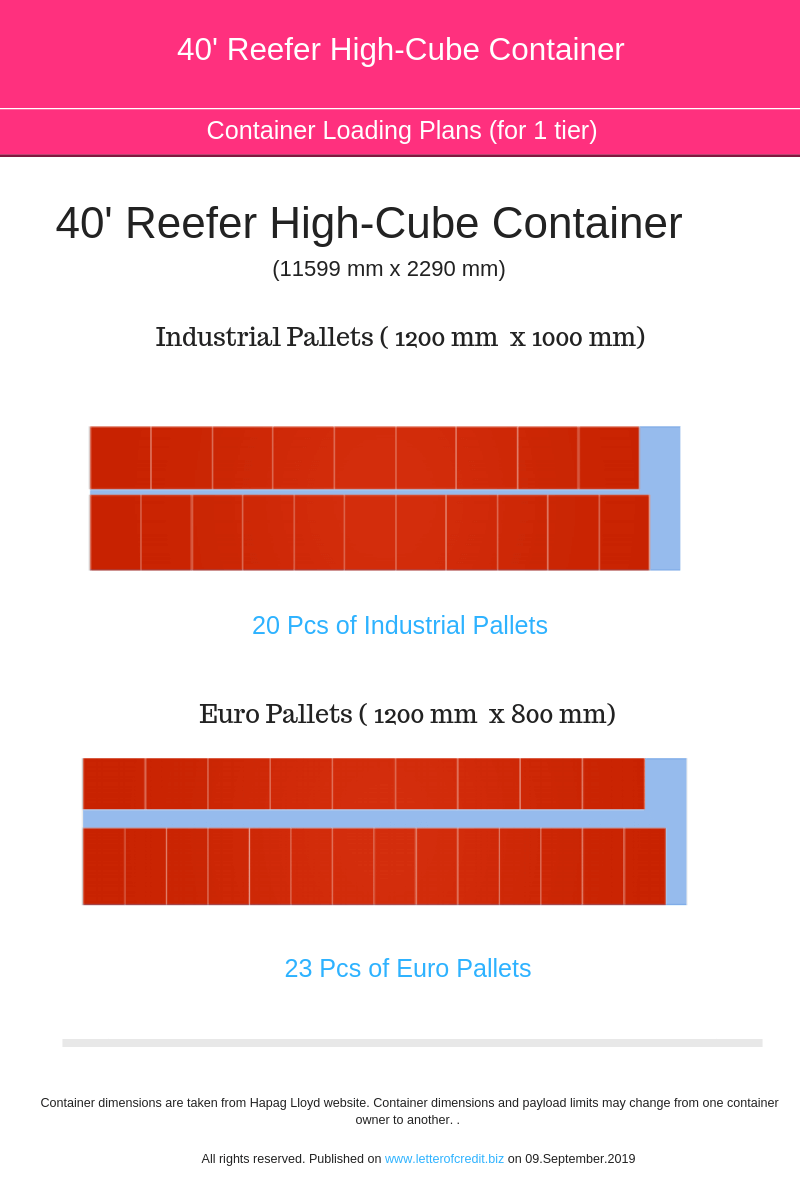

40′ High-Cube Reefer Container Pallet Loading Plans

How Many Pallets Fit in a 40′ High-Cube Reefer Container?

How Many Pallets Fit in a 40′ High-Cube Reefer Container?

Refrigerated container, also known as reefer container or reefer, is a type of container which is equipped with an electrical appliance for the purposes of cooling or heating the air within the container.

40′ high-cube reefer container has the following internal dimensions: Length: 11599 mm, Width: 2290 mm and Height: 2425 mm.

It is possible to fit 20 pcs of industrial pallets and 23 pcs of euro pallets in to a 40′ reefer high-cube container.

20′ Pallet-Wide Container Pallet Loading Plans:

How Many Pallets Fit in a 20′ Pallet-Wide Container?

How Many Pallets Fit in a 20′ Pallet-Wide Container?

A Pallet Wide Container is manufactured approx 4 inches (10.2 cm) wider than a standard width container to enable the stowage of more pallets in a single tier thus eliminating the unused space that can occur in a standard width container.

20′ pallet-wide container internal dimensions:

- Length: 5900 mm

- Width: 2420 mm

- Height: 2385 mm

It is possible to fit 10 pcs of industrial pallets and 14 pcs of euro pallets in to a 20′ pallet-wide container.

40′ High-Cube Pallet-Wide Container Pallet Loading Plans:

How Many Pallets Fit in a 40′ High-Cube Pallet-Wide Container?

A Pallet Wide Container is manufactured approx 4 inches (10.2 cm) wider than a standard width container to enable the stowage of more pallets in a single tier thus eliminating the unused space that can occur in a standard width container.

40′ High-Cube pallet-wide container internal dimensions:

- Length: 12032 mm

- Width: 2420 mm

- Height: 2688 mm

It is possible to fit 24 pcs of industrial pallets and 30 pcs of euro pallets in to a 40′ High-Cube pallet-wide container.

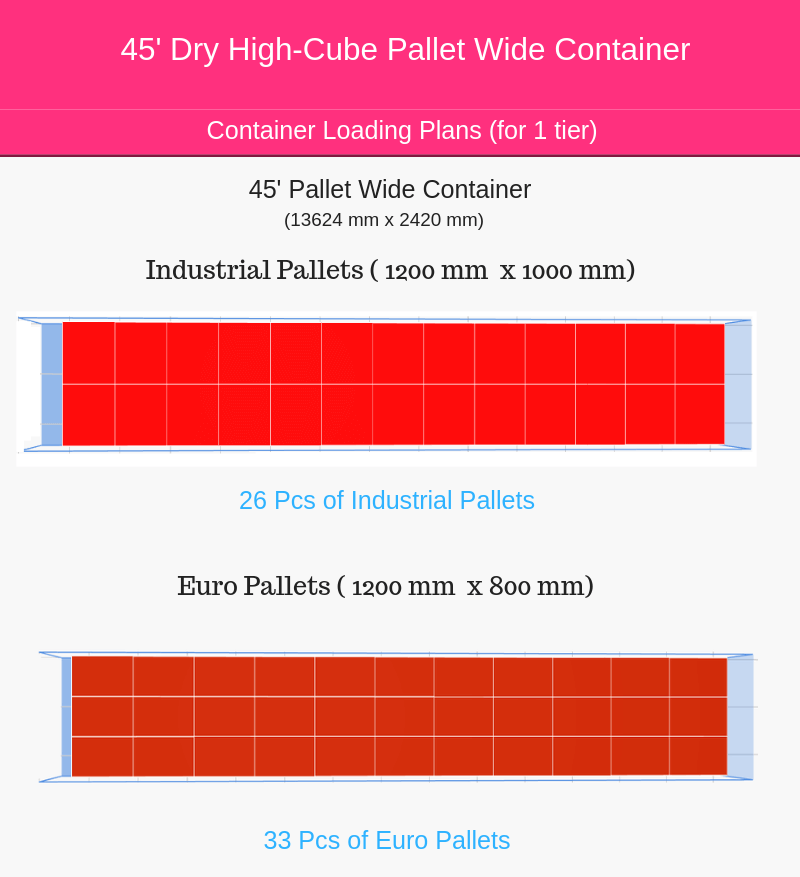

45′ High-Cube Pallet-Wide Container Pallet Loading Plans:

How Many Pallets Fit in a 45′ High-Cube Pallet-Wide Container?

A Pallet Wide Container is manufactured approx 4 inches (10.2 cm) wider than a standard width container to enable the stowage of more pallets in a single tier thus eliminating the unused space that can occur in a standard width container.

45′ High-Cube pallet-wide container internal dimensions:

- Length: 13624 mm

- Width: 2420 mm

- Height: 2694 mm

It is possible to fit 26 pcs of industrial pallets and 33 pcs of euro pallets in to a 45′ High-Cube pallet-wide container.